Plotter Blade Angles

Technical Information

TO DESCRIBE A BLADE BY "THE ANGLE" IS NOT AS MEANINGFUL AS YOU MIGHT THINK

If you search the web for "plotter blade angles" you will find a bewildering amount of inaccurate misinformation.

And because AI reads and absorbs that misinformation it will repeat it.

We design and manufacture plotter blades & Smart Knives

We have been doing it since vinyl cutting machines became popular.

Many of the blades you see advertised elsewhere were manufactured by us or are copies of blades we designed.

For each plotter type we configure blades for particular media ranges.

And there is much more to that than just one angle.

Which is why we don't describe blades by "the" angle.

WHY "The angle" Is not an accurate way to describe a blade type.

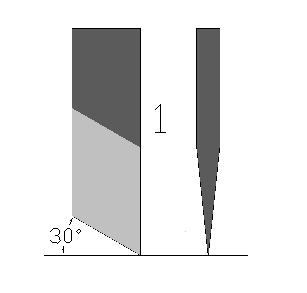

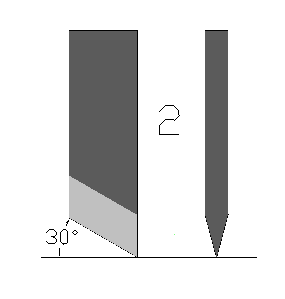

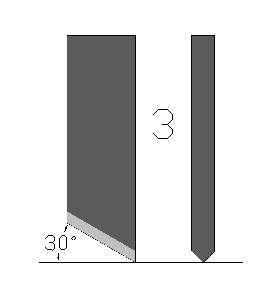

The illustrations above show how a blade can be made using just three of the infinite number of angle compounds that could be used to create a particular approach angle, in the examples shown we have used 30 degrees but it applies to all angles.

1/ Is far too fragile for practical use and the point will break or chip very easily.

2/ Is a more realistic configuration - (for some materials on some plotters)

3/ Might cut butter but it would be useless for almost everything else.

BUT THEY ARE ALL 30 DEGREE BLADES

When people describe a blade as 30 degree (or any other angle) blade which configuration do they mean?

Don’t worry - we can easily establish what you need.

QUESTIONS

Would you expect all cars to use the same tyres?

Or the same wheels as a roman chariot?

Of course you wouldn’t - and they don’t - because they are different.

So why would entirely different plotters which work in entirely different ways use the same blade angle/configuration? -THEY DON'T

And why would just three blade types (30, 45 or 60 degrees) suit all machines? -THEY DON'T

FACTS - Yes - boring facts.

Different plotter types can have entirely different cutting characteristics.

And they need entirely different blade configurations.

Which is why we don't describe them by "the" angle.

IF YOU WANT THE CORRECT BLADE FOR YOUR PLOTTER

Just tell us the make and model of your plotter and the materials you cut.

Why the simplistic (but inaccurate) descriptions 30 45 and 60 degrees became so common.

Most modern plotters now used the in UK are drag cutters.

When those old descriptions became common most plotters in UK were tangential cutters which worked very differently.

There were very few machine types in the UK and very few blade types available so simplistic (but inaccurate) descriptions became common.

FORTY YEARS AGO - BUT NOT NOW

30 degrees described a blade type usually used for “normal” vinyls.

45 degrees described a blade type usually used for some thicker materials.

60 degrees described a blade type usually used for some thick (but soft) sandblast materials.

Those descriptions applied to blades for ONE machine type which was common in the UK 40 years ago.

Those old descriptions still persist, but although they may be described as such, blades now supplied are rarely made to those old configurations because blade design has progressed to become more suited to modern machines and materials.

Perhaps people should stop using meaningless descriptions that were out of date before they were born!

Next time somebody describes a blade as 30 or 45 or 60 Degrees ask them “which angle?”

The answer will be “THE angle” - ask again “which angle?” - the answer will be “THE angle”

People who describe blades by “THE angle” rarely know to which angle they refer (a blade has several relevant angles).

If they think they know which angle they are quoting they rarely know whether it is expressed from vertical or horizontal.

So why do people still use these ancient descriptions?

Because they are a legacy of an era when plotters and materials were very different and blade design was less developed.

When plotters first became available the range of materials they were used to cut was limited so somebody made a blade for a particular machine.

The configuration of that blade (which had many angles) became known as a 30 Degree blade.

(Because ONE of it's angles was 30 degrees)

It could have been made with other angles but 30 degrees was convenient for manufacturing.

As plotters became more popular a wider range of materials developed and some of those were thicker so somebody made a blade to cut them.

Another configuration convenient for manufacturing was chosen and the 45 degree blade was born.

(Because ONE of it's angles was 45 degrees)

Further material developments put more demands of the limited power of machines and gave rise to the production of a 60 degree blade

(Because ONE of it's angles was 60 degrees)

Do these blade angles still apply 40 years later?

Sometimes, but only when the correct compound of angles have been used to create them.

As you can see in the illustrations above the other angles in the compound are more important than “THE angle” so unless you are a toolmaker, a metallurgist and a mathematician who can calculate and specify the compound of angles needed to create the cutting edge of a blade it is much better to tell us what plotter you have and what materials you cut rather than to provide a meaningless inaccurate (and ancient) description.